Tim Mack

Submitted by Tim Mack on

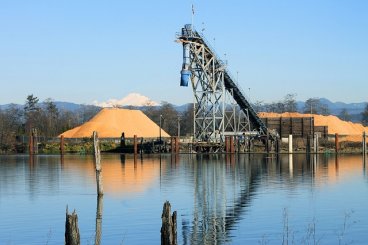

It is a measure of the times to see economic sectors that have historically been substantial producers of byproduct waste take a hard look at what they have been ignoring. One such sector is the forest products industry, which had normally burned its sawdust—much like natural gas was initially burned off by the petroleum industry until they began storing it back underground elsewhere, initially in salt mines.

The factors driving this sea change are many, and one site of this expanded focus has been Europe, particularly Italy and Spain. In some cases, the research behind innovative uses of forest product waste is being funded by innovative and entrepreneurial companies such as CMC Texpan in Italy and HONEXT in Spain (versus, for example, the national lab systems in the U.S.).

In Colzate, Italy, Texpan utilized the first half of 2020 (during the COVID shutdown) to introduce a new processing technology called Lynx (based on SWIR spectroscopy), which automatically identifies and removes contaminants and pollutants—such as plastics, foam, silicone, and polystyrene—from recycled wood-based products, as well as wood waste, chips, and particles. The technology is projected to address higher density materials such as ferrous and nonferrous metals, aluminum, copper, lead, and a range of alloys using X-ray and color-sensing systems. The development of a consolidated inspection line is expected to meet some of the challenges of rapidly diminishing fresh wood resources that is facing Europe.

In contrast to the Italian approach, the Barcelona company focuses on the waste stream from paper production. The driver for HONEXT is a combination of its forecast of raw material supply being outrun by product demand in the coming decades and its identification of a usable pulp and paper industry waste product. Specifically, the residue recovered from the wastewater stream (termed sludge) has historically been sent to landfills. As well, corrugated cardboard, or OCC, utilized for packing and packaging, has been a growing material resource, in part because of the substantial surge of online shopping and shipping. In this case, the Universitat Politecrica de Catalunya in Barcelona spun out HONEXT, which utilizes a new waste reclaiming technology that turns cellulose residue into a construction-ready material (for example, medium density fiberboard, or MDF, with a combination of 75% paper sludge and 25% cardboard waste).

The process is resin free and accomplished without CO2 emissions, resulting in a new range of products that are nontoxic, long lasting, and sustainable. This nonlinear process uses a circular economic model of waste collection to material generation that could be termed cradle to cradle, thus falling into line with environmental, social, and governance (ESG) standards. The ideal will be the development of distributed production networks, where waste is transformed to product at the point of waste generation.

While my previous Foresight Signals articles have focused on environmental innovation in the United States, it is encouraging to observe the level of investment and creativity being brought to bear in this arena in the EU.

References

Stephen Powney, “Lynx Cleans Up Recycled Wood,” Wood Based Panels International (October/November 2021; posted online November 16).

Geoff Rhodes, “What the Future Holds?” Wood Based Panels International (October/November 2021; posted online November 16).

About the Author

Timothy C. Mack is managing principal of AAI Foresight Inc. and former president of the World Future Society (2004–14). He may be reached at tcm333@gmail.com.

Image credit: Deborah Jackson from Pixabay